How Innovations in Carpentry Are Shaping Modern Woodworking

Carpentry is one of the oldest trades in the world, and it’s one that is deeply rooted in both tradition and craftsmanship.

However, recent technological advancements have ushered in a new era for woodworking.

These innovations have dramatically reshaped the world of carpentry and custom woodworking, enhancing precision, efficiency, and creativity for both carpenters and clients alike.

With that in mind, if you want to learn more about innovations in carpentry that are revolutionizing the woodworking industry, then this article is for you.

Exploring Innovations in Carpentry

Innovations in carpentry are driving a transformative shift in woodworking practices.

From digital design tools and advanced machinery to sustainability measures and smart technologies, modern innovations have enhanced precision, efficiency, safety, and creativity.

So, let’s explore some of the most important advancements that are redefining the woodworking landscape.

Digital Design and Precision Woodworking

One of the most significant innovations in carpentry today is the widespread adoption of digital design tools.

Software programs like AutoCAD, SketchUp, and Fusion 360 have revolutionized how carpenters approach projects.

These tools enable precise planning, accurate visualization, and easy modifications, which helps clients to better understand and visualize final products.

For instance, before any woodworking begins, carpenters can create a detailed 3D model that clients can explore virtually.

Adjustments to design elements like dimensions, materials, or aesthetic details can be quickly made, ensuring that the final product meets exact specifications and client expectations.

What’s more, digital design reduces material waste by accurately predicting the exact amount of wood and other materials that will be needed for a given project.

And this is particularly beneficial from both environmental and cost-saving perspectives.

Smart Tools and IoT Integration

Internet of Things (IoT) technology has reached the woodworking sector, with some smart tools offering impressive functionality.

From moisture meters and digital measuring tapes to smart saws and connected sanders, IoT-enabled tools are helping carpenters to become more efficient and accurate.

For example, smart moisture meters automatically transmit data to a mobile device, ensuring carpenters can precisely monitor wood conditions, which reduces errors related to material quality.

Similarly, smart saws can offer digital readouts and cutting recommendations based on specific project requirements, which improves both precision and safety.

IoT connectivity also enables remote monitoring and maintenance of tools, ensuring that equipment remains in peak condition and issues are addressed as soon as possible.

CNC Machines: Revolutionizing Precision and Consistency

Computer Numerical Control (CNC) machines represent one of the most powerful innovations in the world of modern carpentry.

These machines offer unprecedented precision, consistency, and speed.

And unlike traditional woodworking tools, CNC machines use computerized controls to carve and shape wood, resulting in flawless outcomes each and every time.

A CNC router, for example, can intricately carve designs or components that are consistently identical across multiple pieces.

This is invaluable for things like custom cabinetry, intricate decorative elements, and complex joinery techniques that previously required extensive manual labour and a high risk of human error.

The efficiency of CNC machines also means reduced production times, which allows carpenters to take on more projects and complete orders faster.

Augmented Reality: Visualizing Woodworking Projects

Augmented reality (AR) applications are gradually making their way into carpentry workshops.

AR apps allow carpenters and clients to overlay digital models of furniture or installations onto real-world environments.

This technology provides clients with a realistic preview of how the final piece will look in their own homes or commercial spaces.

AR also benefits carpenters by assisting in complex assembly processes.

By using AR glasses or mobile devices, carpenters can visualize step-by-step instructions directly onto their workpiece, drastically reducing the time and potential mistakes involved in assembly.

Moreover, AR helps carpenters to efficiently plan spatial configurations and ensure that finished projects fit perfectly into their intended spaces.

Sustainable Innovations in Woodworking

Another area seeing significant innovation in carpentry is sustainability, as new eco-friendly practices and materials are becoming increasingly important.

For instance, reclaimed wood, bamboo, and composite materials made from recycled products are now popular choices, especially among environmentally conscious clients.

Moreover, advanced finishing techniques also contribute to this increased sustainability.

Water-based finishes, low-VOC adhesives, and non-toxic treatments, for example, can also make woodworking projects more environmentally friendly.

Sustainable innovations also include improved waste management techniques and energy-efficient machinery, both of which help to reduce the environmental impact of woodworking.

Robotics and Automation in Woodworking

Robotics is entering the world of carpentry, starting with automated production lines and robotic assistants in workshops.

Robotic arms, for instance, equipped with precise cutting, drilling, and sanding capabilities, can perform repetitive tasks with high speed and reliability, allowing human carpenters to focus more on creativity, customization, and quality control.

Automation also ensures a safer working environment. Robots can handle dangerous tasks, reduce the risk of injuries, and create more ergonomic and comfortable conditions for carpenters.

Moreover, robotic systems enhance productivity by working continuously without fatigue, and this enables round-the-clock operations and a significantly increased output.

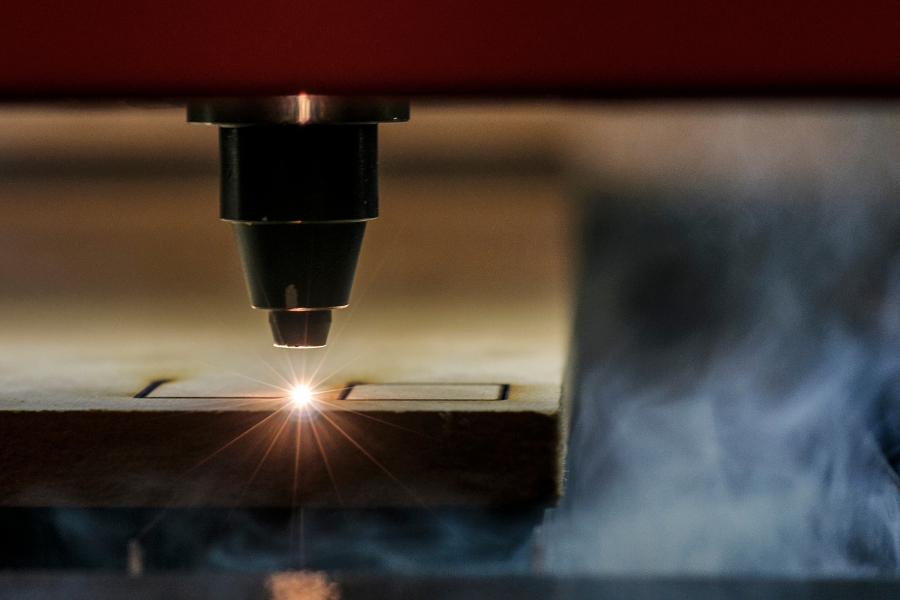

Laser Technology to Enhance Detail Work

Laser cutting and engraving represent further advancements in woodworking technology.

Laser cutters provide extreme precision, enabling woodworkers to create intricate patterns and precise cuts that would be nearly impossible to achieve by hand.

Laser engraving also opens the door for unique customization opportunities.

Whether you’re personalizing furniture pieces, cabinetry, or artistic decorative items, laser technology ensures detailed, clean, and beautiful results that are bound to elevate the aesthetic appeal of carpentry projects.

Furthermore, laser technology helps to reduce errors and waste, as the accuracy of laser cutters ensures minimal wood is wasted.

Enhanced Safety Gear and Workshop Equipment

Innovations in personal protective equipment and workshop safety gear are another critical aspect of modern carpentry.

From intelligent dust extraction systems and air filtration to enhanced hearing and eye protection with built-in digital functionality, modern safety equipment significantly reduces the risks associated with woodworking.

Dust extraction technologies now integrate sensors that detect air quality in real-time, so they can automatically adjust their extraction rate to ensure optimal working conditions.

Advanced eyewear and helmets are equipped with heads-up displays, which provide essential data without distracting the user.

And innovations in ergonomic equipment further improve worker health and longevity by reducing strain injuries that are common in traditional woodworking environments.

Training and Skill Development With Virtual Reality

Virtual reality (VR) is also playing a role in woodworking by revolutionizing training and skill development.

VR simulators enable novice carpenters to practice intricate woodworking techniques in a virtual, risk-free environment, which significantly reduces the learning curve and prepares workers for real-world applications by giving them higher confidence and competence.

In addition, VR training modules can teach essential woodworking skills, including joinery, machine operation, and safety protocols.

VR also helps to enhance professional development, as it allows experienced carpenters to learn advanced techniques and stay current with all the latest technological advancements.

Are you looking for a carpenter in Kelowna?

Our master woodworker, Andy Ingram, has over 30 years of experience. For more details, contact us or check out our portfolio to see what we’re capable of creating.